No stopping

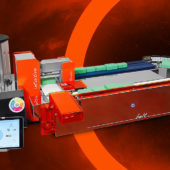

RiaceWax has been able to transfer its technological know-how in the gold industry by focusing on the production of an innovative machinery which remains ahead of the market’s demands thanks to its continuous progress and development.

Innovation

The new modular RiaceWax system optimizes the wax injection process contributing to the reduction of waste and effort. It always guarantees excellent results and a precise dosage of melted wax inside the mold.