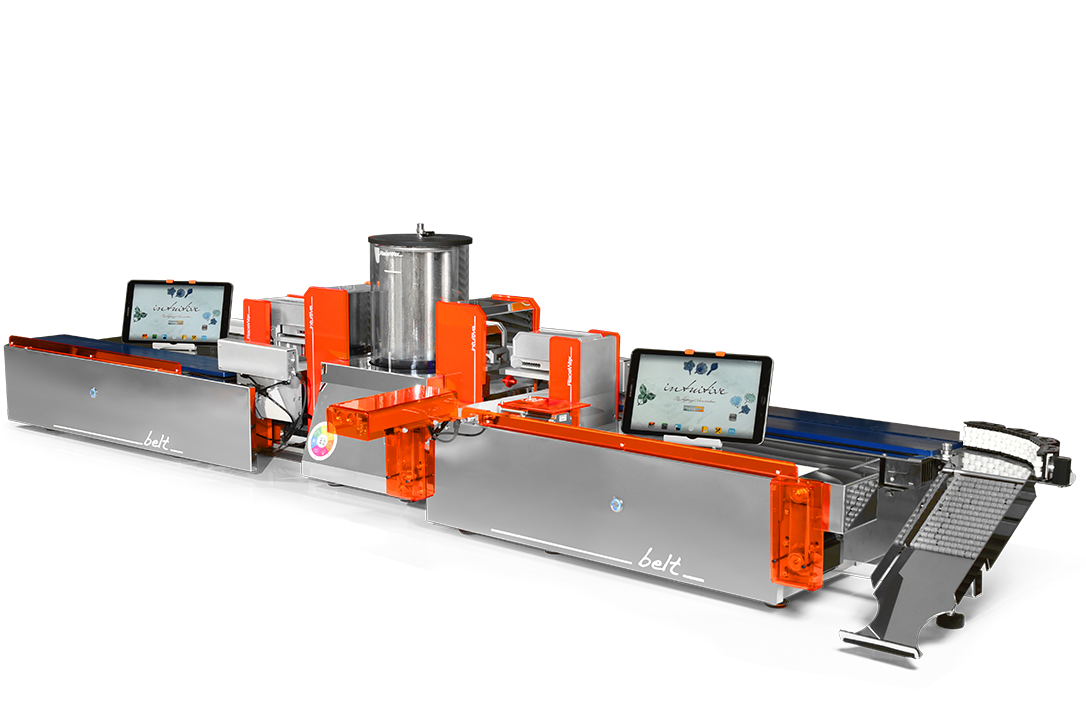

Fully controllable from a 10.1” industrial PC, it can quadruple the standard daily production, creating up to 9600 in 8 hours of work with the help of two operators, injecting molds of very different sizes and reducing the number of defective waxes.

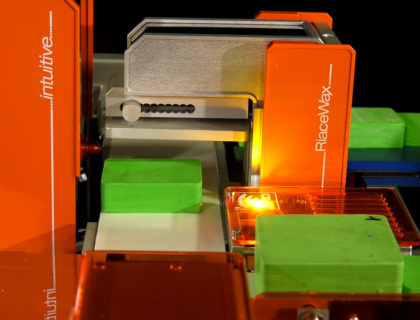

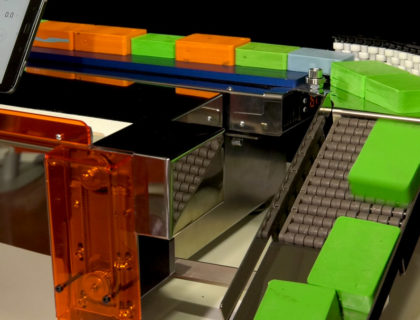

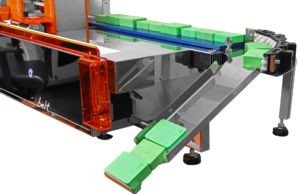

The AUTOMATIC BI BELT SYSTEM INTUITIVE injector belongs to the Intuitive line and retains all its features; it can inject up to 20 moulds of different sizes at the same time and per workstation by loading them automatically and speeding up the entire production process thanks to the self-centering function of the molds of different sizes; it can create light and very thin objects, maintaining their weight over time.

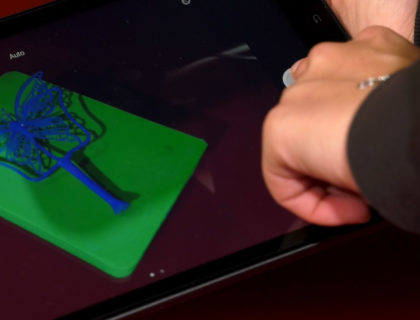

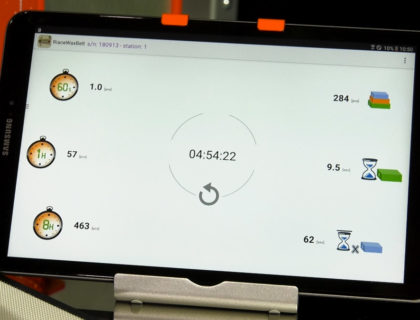

Two Android tablets are the control unit of both the machine and the loading system, with specially developed apps that also allow to check statistics and productivity. Thanks to the ability to connect remotely it is compatible for Industry 4.0.

It is equipped with a transparent melting tank with a constant vacuum system, digital sensors to control the pressures that always allow to check the graphs of the vacuum trend on the molds during injection from the tablets, RFID readers, TC-700 coolers, 8-cmc injection syringes with final temperature regulation and self-centering clamps with 120x90mm plates.