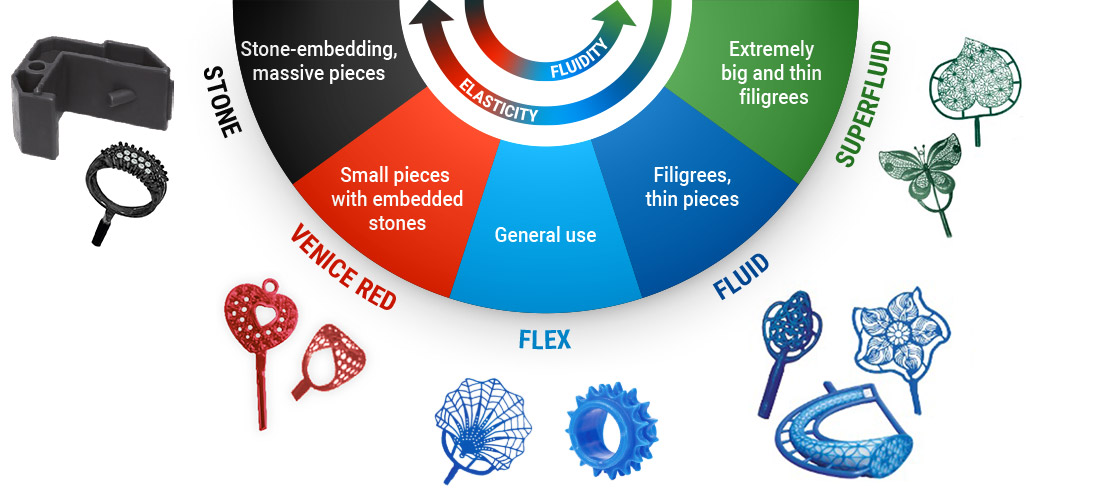

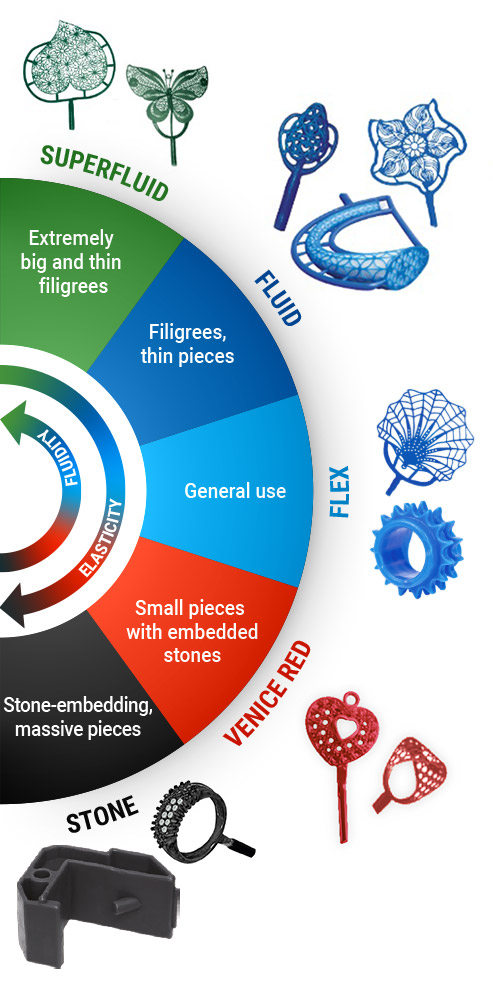

Flexible Wax

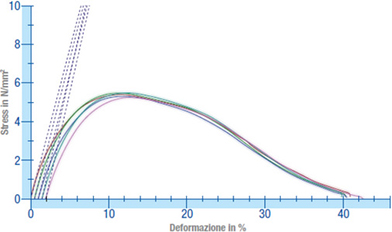

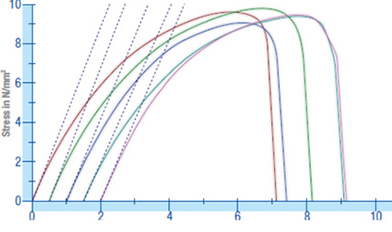

An extremely versatile wax suitable for general use and, therefore, for the creation of all types of objects. Its good fluidity and excellent flexibility guarantee a perfect filling, which makes it appropriate for thin molds and filigrees. Its medium level of shrinkage allows its use even for large pieces.

Its excellent elasticity facilitates the extraction without any breakages.

-

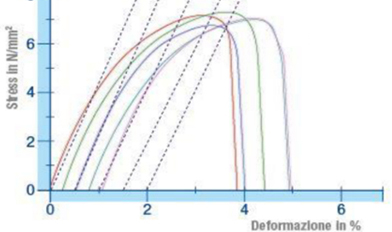

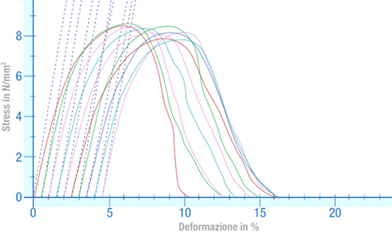

Stiffness of material or elastic moduls160 N/mm2

-

Maximum sustainable effort by the material5.5 N/mm²

-

Linear shrinkage (injection T 65° C)3.1%

-

Residue after combustion0.0.3%

-

Fluidity M.F.I. (65°C - 2.16kg)500g/10'

-

Humidity<1%

Working temperature

-

Massive objects68 - 70 °C

-

Thin objects72 - 74 °C

-

Watermarks74 - 78 °C

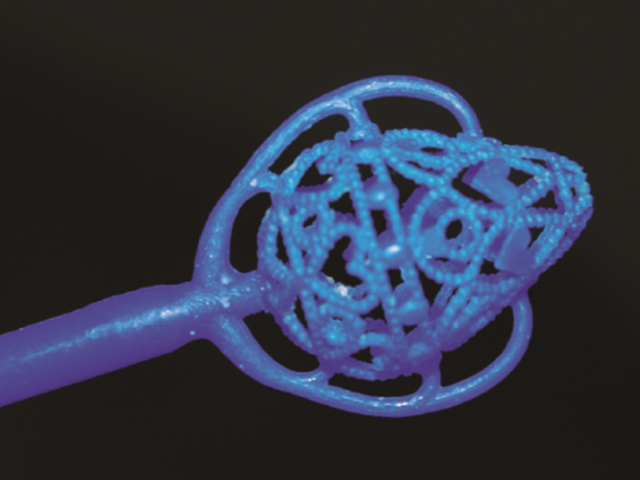

Fluid Extruded Wax

A particularly smooth wax specifically designed for the combined use with hydro resin. The high fluidity and the high cooling time allow the creation of particularly thin and filigreed objects equipped with a hydro resin core.

-

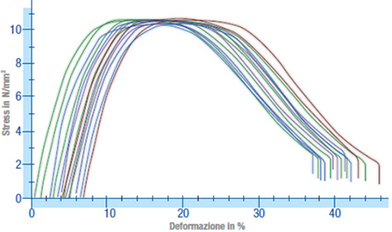

Stiffness of material or elastic moduls425 N/mm²

-

Maximum sustainable effort by the material9.5 N/mm²

-

Linear shrinkage (injection T 65° C)3.3%

-

Residue after combustion0.0.3%

-

Fluidity M.F.I. (65°C - 2.16kg)1130g/10'

-

Humidity<1%

Working temperature

-

Massive objects68 - 70 °C

-

Thin objects74 °C

Stone Extruded Wax

Particularly suitable for massive objects, characterized by a good fluidity, a low shrinkage and a great elasticity, which makes the setting of stones in the models easy. The high flexibility allows the extraction of the piece from the mold without any breakages.

-

Stiffness of material or elastic moduls160 N/mm²

-

Maximum sustainable effort by the material10.54 N/mm²

-

Linear shrinkage (injection T 65° C)2.9%

-

Residue after combustion0.0.3%

-

Fluidity M.F.I. (65°C - 2.16kg)1130g/10'

-

Humidity<1%

Working temperature

-

Massive objects74 °C

-

Thin objects76 - 78 °C

-

Watermarks78 - 80 °C

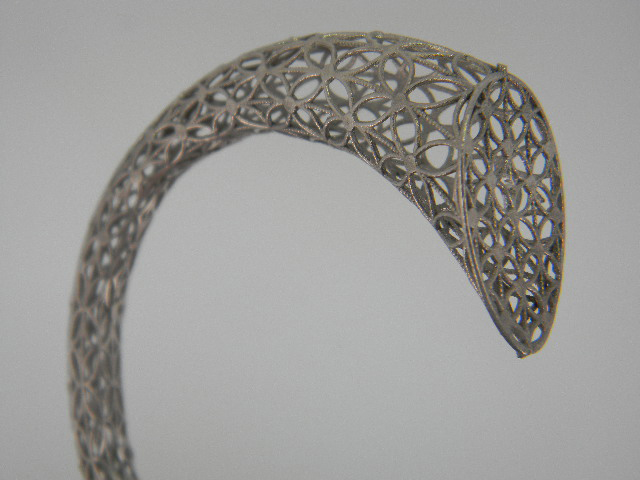

Superfluid Extruded Wax

The Superfluid is an innovative wax designed to have a very low viscosity and it can produce both the thinnest and the largest filigrees. It flows like water even at a low injection temperature (60-70 °C) and this allows to obtain incredibly capillary designs that are less than 0.3 mm thick.

-

Stiffness of material or elastic moduls220 N/mm²

-

Maximum sustainable effort by the material7.2 N/mm²

-

Linear shrinkage (injection T 65° C)3.6%

-

Residue after combustion0.0.3%

-

Fluidity M.F.I. (65°C - 2.16kg)2020g/10'

-

Humidity<1%

Working temperature

-

Massive objectsOggetti massivi70 °C

-

Watermarks72 °C

Venice Extruded Wax

Born with the idea of combining the characteristics of the Flex and the Stone: it is a wax with intermediate properties, compact and elastic but with a good fluidity.It is designed for those who have pieces with settings or difficult to remove from the mold but, at the same time, do not want to work with a hard and viscous wax.

-

Stiffness of material or elastic moduls160 N/mm²

-

Maximum sustainable effort by the material8.5 N/mm²

-

Linear shrinkage (injection T 65° C)2.5%

-

Residue after combustion0.0.3%

-

Fluidity M.F.I. (65°C - 2.16kg)450g/10'

-

Humidity<1%

Working temperature

-

Massive objects65 °C

-

Watermarks74 °C

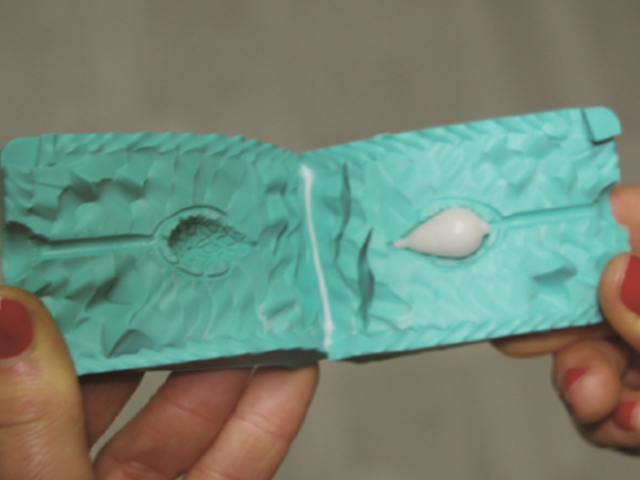

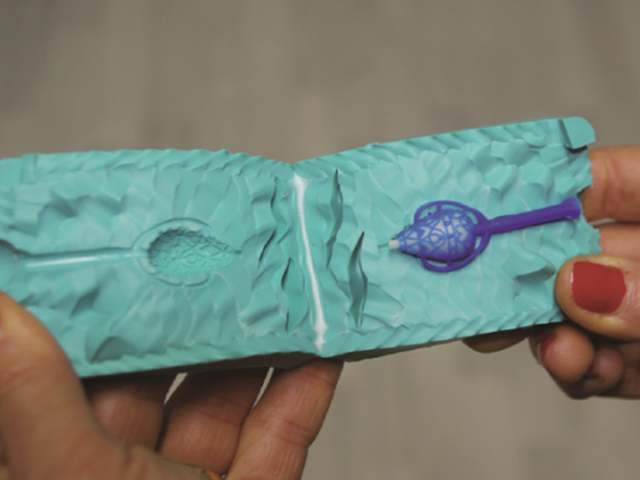

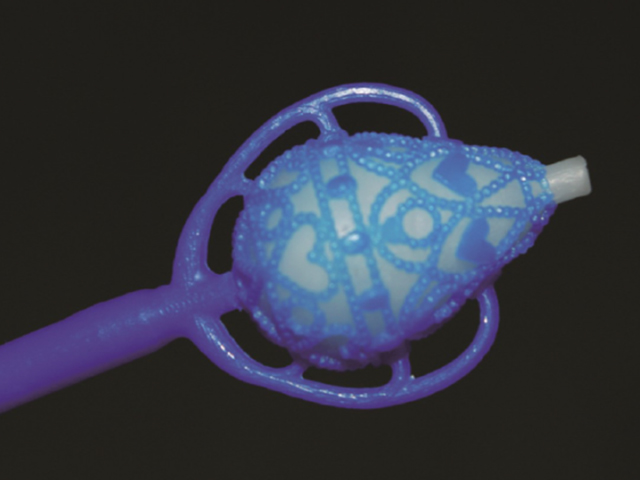

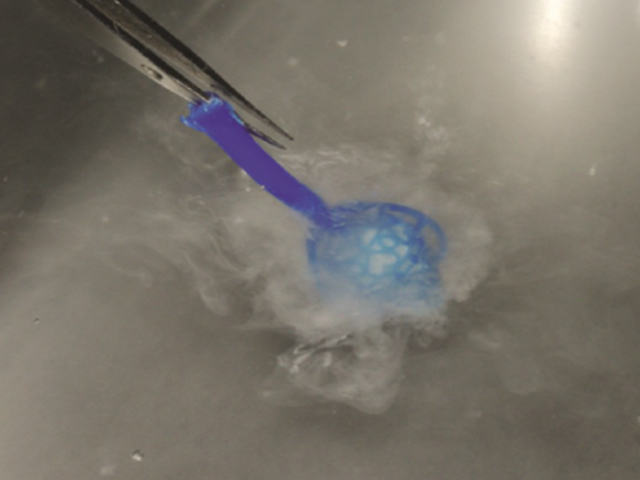

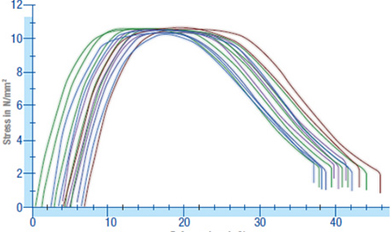

Hydro Resin

Hydro Resin Process

THE NEW FRONTIER OF THE WAX 3D

Sensitive to market demands, Riacetech has developed a wax injection process on a water-soluble support. In this way, it will be possible to create 3D filigree and hollow objects, using normal wax and going beyond the bound of removing the rubber interior.

Main advantages over prototyping technology:

• Economical for large productions – the cost of hydro resin is 5 times lower.

• Final wax piece – the problems related to resin fusion are avoided.

• Number of daily pieces produced above that of any prototyping machine.

• Soluble in water without the use of acids, avoiding the consequent problems of disposal.

• Complete non-toxicity.

• Use of one of our standard injectors – no cost for special machines

Hydro Resin

Designed for hollow objects, hydro resin is 100% non-toxic and soluble in warm water without the need to use acids. It allows the quick creation of hollow pieces without causing wax melting problems. Thanks to its excellent mechanical resistance, the extraction of the pieces is simple and ensures no breakage.

Working temperature

-

Massive objects65 °C

-

Watermarks74 °C